Control panels are critical components in industrial processes responsible for managing the equipment that powers your operations. When control panels fail, the consequences can be severe, leading to production losses, missed deadlines, and, in some cases, safety concerns.

To keep your industrial processes running smoothly, you must know how to troubleshoot control panel issues and identify the most common problems to avoid them. We’ll explore some common control panel issues and provide some troubleshooting tips.

Power Issues

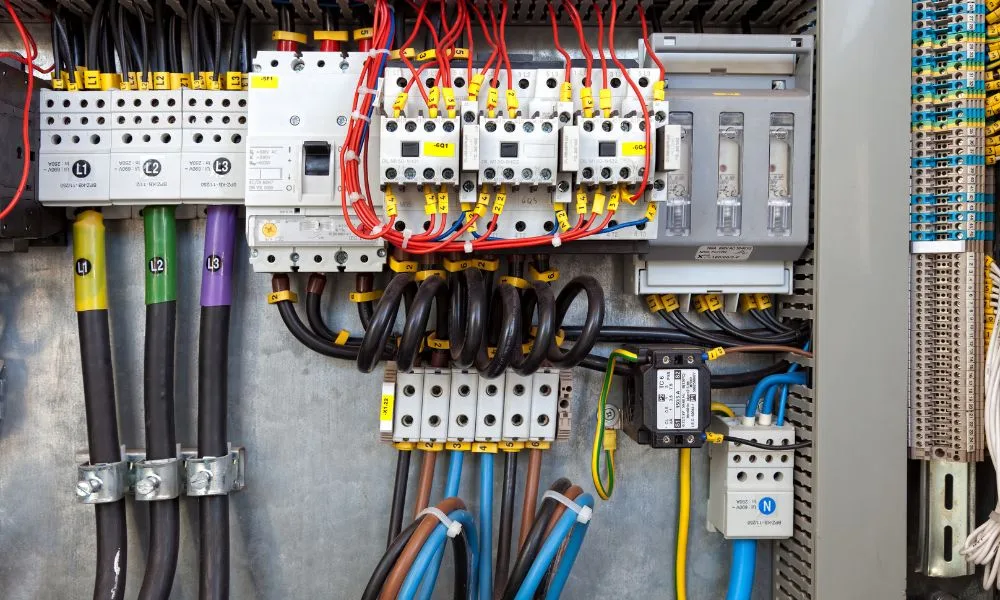

Some of the most common control panel issues are power-related problems. The control panel might not receive the necessary power supply due to a blown fuse, tripped circuit breaker, or loose wiring connections. To address this issue, you can start by checking the fuse or circuit breaker and replacing them if they’re malfunctioning. You can also check the wiring connections to ensure they are properly installed and secure.

Faulty Control Components

Another common issue with control panels is faulty control components. Control components, such as relays, transformers, and circuit breakers, can fail due to regular wear and tear, overloaded circuits, or improper installation. If you suspect one of the control components is faulty, you can use a multimeter to check its functionality and replace it if necessary.

Programming Errors

If your control panel is programmable, programming errors could lead to malfunctions in the control panel. The errors may occur due to incorrect programming or firmware updates you installed. To address programming errors, you can start by checking the program parameters and reinstalling the firmware with the help of technical support.

Environmental Factors

Control panels operating in harsh environments are prone to problems due to extreme temperatures, humidity, dust, and vibrations. Severe environmental conditions can lead to wiring corrosion, component failures, and damaged circuit boards. To mitigate the environmental impact, you can install cooling fans, filters, and housing enclosures to protect the control panel components.

Human Errors

Control panel issues can also occur due to human errors, such as incorrect installation, maintenance, or operation. To address human error, provide ongoing training to operators and technicians, develop standard procedures for installation and maintenance, and conduct regular inspections and audits of the control panels.

Control panel issues can be frustrating for industrial processes looking to run smoothly and consistently. However, with the right knowledge and expertise, troubleshooting common control panel issues can be straightforward. Some common issues highlighted in this post include power issues, faulty control components, programming errors, environmental factors, and human errors. By being well-versed in these issues and how to address them, you can minimize downtime and mitigate the impact of control panel problems on your industrial processes.

If you need an industrial control panel, Xpect Solutions offers a wide selection of reliable, high-performance control panels from leading brands. Our experienced team can guide you through choosing, installing, and maintaining a control panel to ensure optimal operation. Contact us today to learn more about our services!