Businesses should always look for ways to improve their packing processes. After all, they want to create a more efficient and effective way to remain profitable. One piece of packaging equipment you may not have thought of for your facility is a lid press machine. Use this brief overview of automatic lidding machines in packaging to discover what they are, their benefits, and the industries that can use them.

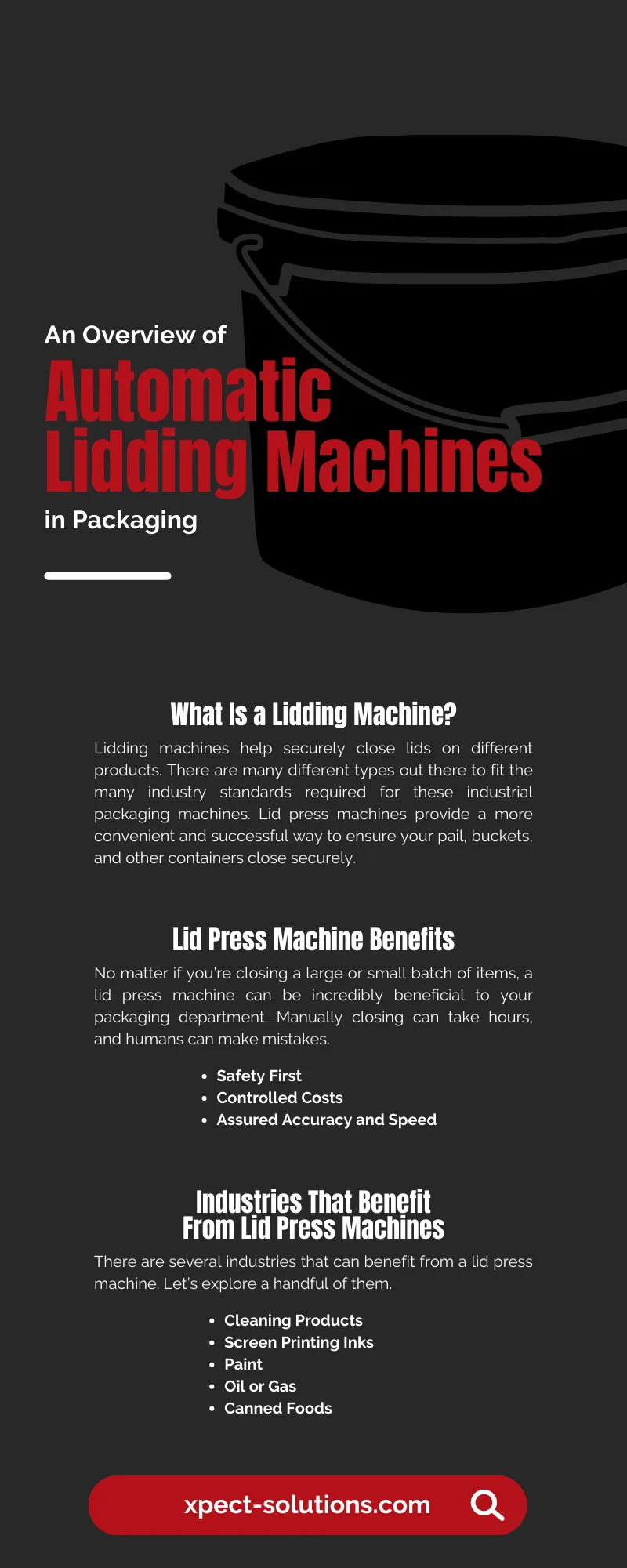

What Is a Lidding Machine?

Lidding machines help securely close lids on different products. There are many different types out there to fit the many industry standards required for these industrial packaging machines. Xpect Solutions offers various lid press machines. We even provide custom machinery, ensuring the product will fit your individual needs.

Customers need to stay competitive in their industry. You should address every area of improvement you can to give yourself an edge over the competition. Lid press machines provide a more convenient and successful way to ensure your pail, buckets, and other containers close securely.

Lid Press Machine Benefits

How often are you assessing the risk in your packaging process? How do you ensure the pails or containers remain sealed during the process? Is there a chance the containers will spill, leak, or break open during transportation or storage? No matter if you’re closing a large or small batch of items, a lid press machine can be incredibly beneficial to your packaging department. Manually closing can take hours, and humans can make mistakes.

Xpect Solutions has several types of automatic lid press machines available to provide these benefits.

Safety First

Safety is the top benefit lid press machines provide. Gone are the days of inconsistency, and you’re eliminating human error. There’s a chance an employee won’t seal the container correctly, or they could harm their fingers—not to mention the physical strain team members endure when handling packaging. It’s a labor-intensive process that quickly becomes exhausting.

Finding the right lid press machine will make all the difference in the safety of your facility. Add conveyors and rollers to the stand-up or table-top machinery to ensure employees spend less time moving and lifting. They’ll expel less time and energy hauling heaving items and focus their attention on providing properly closed containers.

Controlled Costs

Lid press machines enable a facility to provide cost-cutting and control. This is usually an overlooked benefit that these incredible devices offer. These machines first help control costs by increasing the sealing or re-sealing process. This benefit frees up valuable staff members to tackle more important tasks during the work day. Fewer trained employees can handle more work in a shorter period and then move on to more pressing matters or other parts of the packing process.

This benefit keeps labor costs down and maximizes the amount of work team members tackle in a workday, which also reduces production costs. For example, a facility with a lid press machine can customize the process to include sealing and packaging in the same area as production.

Even if you’re using the lid press machine for re-sealing, it still lowers costs. An improperly-sealed container could become unstable, spoil, degrade, or become unusable. A lid press machine provides peace of mind that your team re-sealed the container properly, keeping production costs down.

Assured Accuracy and Speed

You can trust the lid press machine to be more accurate and efficient than a human. Leaking isn’t acceptable, no matter what industry you’re dealing with. Manual machines can’t guarantee that the closed container won’t leak. Unfortunately, team members can become distracted or work too quickly. A fast-paced environment can lead to accidents and other detrimental occurrences.

Investing in a lid press machine can eliminate these concerns. You can rest assured that every container receives the proper seal and that the device completes the process faster than any employee could.

Industries That Benefit From Lid Press Machines

There are several industries that can benefit from a lid press machine. Let’s explore a handful of them.

Cleaning Products

Residential and commercial industries can benefit from cleaning products. If your facility packages cleaning products, a lid press machine can help in more ways than one. Firstly, the device will ensure the chemicals stay in the packing where they belong, ensuring they arrive as clients expect.

That said, it’s worth noting that cleaning products typically contain toxic ingredients that could be hazardous if spilled. The fumes could be dangerous, too. An accidental spill in the warehouse or on the delivery truck could harm the team members handling the product and the customers purchasing the items. This factor makes reliable seals even more crucial.

Screen Printing Inks

A lid press machine can be incredibly helpful for those in the screen printing ink industry. The cost of the ink can be high, and allowing accidental spills to happen can eliminate any profit. Using the proper machinery will ensure the ink is safe and secure after the sealing process.

Paint

Paint is likely the most well-known industry that can benefit from a lid press machine. The device will easily streamline the packaging process for paint used in residential or commercial spaces. If a can, pail, or bucket of paint has an opening, the product could dry out or spill.

A lid press machine guarantees the product ends up in the consumers’ hands in optimal form. Plus, cleaning up spilled paint is a costly expense. You’ll begin to see the savings rack up over time after making the investment in a lid press machine.

Oil or Gas

The oil or gas industry is another area that can greatly benefit from a lid press machine. Since the device is customizable, your facility can find the best size for the business. It ensures the product stays inside the container during shipping and storage.

Say goodbye to the hand-operated capseal crimping tool that typically closes the oil and gas barrels. Updating these outdated tools will increase productivity and profits. Xpect Solutions creates lid press machines large enough to fit whatever size barrel your facility needs.

Canned Foods

The canning process is vital to the food industry because it keeps nutritious foods fresh. Plus, it makes items more affordable for customers. A lid press machine is important for the canned food industry because it helps complete the process efficiently and effectively. This proper sealing process protects business owners from costly recalls and prevents customers from consuming contaminated foods.

This overview of automatic lidding machines in packaging should demonstrate the key role these machines can play across industries. Xpect Solutions is here to answer any questions you may have about our automatic lidding machines. We’ll be more than happy to help you choose which one is right for your facility.